In the realm of contemporary agriculture and animal husbandry, feed production efficiency and quality are critical factors. The electric feed pelleting machine is one of the most inventive devices that has transformed this industry. In addition to discussing important topics like pellet machine cost and how to locate a feed pellet machine for sale nearby, this post will examine the uses, benefits, and features of electric feed pelleting machines.

An electric feed pelletizing machine: what is it?

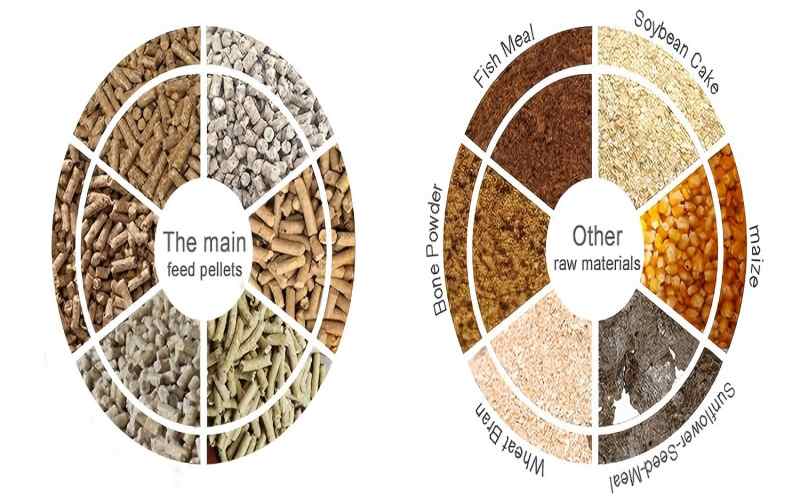

An electric feed pelleting machine, sometimes referred to as a feed pellet mill for feed or a feed pellet producing machine for sale, is a specialized piece of machinery used to turn raw materials into small, nutrient-dense pellets that are suitable for animal feeding. Animal, poultry, aquaculture, and even pet feed are all produced using these equipment. Compressed into tiny, homogeneous pellets, the raw materials usually consist of grains, corn, soybean meal, wheat bran and other agricultural waste.

Electric feed pelleting machines produce a more robust and practical type of feed than traditional feed processing techniques, which frequently produce loose, dusty feed that is prone to spoiling and waste.Because they run on electricity, they are energy-efficient and appropriate for both huge industrial settings and small to medium-sized businesses.

Essential Features of an Electric Feed Pelletizer

1. Pellet formation and feed processing

Converting raw feed materials into compact pellets is the main purpose of an electric feed pelleting machine. In this process, the raw ingredients are ground into a fine powder, combined with any necessary binders or additives, and then compressed under high pressure via a die. The end product is a uniformly dense pellet that is simple to transport, store, and feed to animals.

Depending on the kind of animal they are meant for, the pellets made by a livestock feed pellet mill are usually cylindrical in shape and range in size. For example, larger pellets might be appropriate for cattle or pigs, whereas smaller pellets are best for chickens and other birds. This personalization guarantees that the feed satisfies the animals’ unique nutritional and physical requirements.

2. Enhanced Nutritiousness

The heat and pressure produced during the pelleting process aid in the breakdown of complex nutrients and the gelatinization of starches, improving animal digestion. Furthermore, the procedure might lessen the amount of dangerous germs present, guaranteeing safer animal feed.

This translates into healthier animals, quicker development rates, and increased productivity for farmers wishing to purchase an animal feed pellet mill. A balanced meal catered to the animals’ requirements is further ensured by the option to add vitamins, minerals, and other supplements during the mixing stage.

3. Decrease in Feed Waste

Because of spills or animals’ selective feeding, loose feed frequently results in large waste. This problem is solved by electric feed pelleting machines, which produce consistent pellets that are less prone to crumble or scatter. In addition to saving farmers money, this guarantees that animals eat the entire spectrum of nutrients found in the feed.

Purchasing a high-quality pellet machine might result in considerable long-term savings if you’re looking for a livestock feed pellet machine to reduce waste on your farm. Because pellets are tiny, it’s also simpler to measure and distribute them, which guarantees reliable feeding procedures.

4. Improved Transportation and Storage of Feed

Compared to loose feed, pellets made by a feed pellet mill are far more resilient and less likely to spoil. Because of their small size, less feed is needed for storage, which saves space and improves efficiency. Pellets also have a lower propensity to absorb moisture, which prolongs shelf life and inhibits the growth of mould.

A feed pellet mill can reduce transportation costs for businesses engaged in large-scale feed production or distribution. Pellets’ higher density and decreased volume allow for the transportation of more feed in a single trip, which lowers logistics expenses.

5. Flexibility in the Production of Feed

Because of its great versatility, electric feed pelleting machines can be used to provide feed for a variety of animals, including fish, cattle, sheep, pigs, poultry, and even pets. Users can produce pellets of different sizes and hardness to fit different species by modifying the die and roller settings.

Advantages of Electric Feed Pelleting Equipment Use

1. Economicalness

Even while the initial cost of the pellet machine might seem exorbitant, there are significant long-term cost advantages. You can have more control over the cost and quality of materials and lessen your dependency on commercial feed suppliers by making your own feed pellets. Additionally, your farm or business may become more profitable as a result of the decreased feed waste and enhanced animal health.

2. Efficiency in Energy Use

When opposed to diesel-powered alternatives, electric feed pelleting machines are made to use less energy. Small to medium-sized farmers that wish to reduce operational expenses while preserving excellent yield would find them suitable. To get the most out of your investment, look for feed pellet machines for sale in your area that have energy-saving features.

3. Usability and Maintenance Ease

With simple controls and little training needed to operate, the majority of contemporary electric feed pelleting machines are easy to use. With easily cleaned and maintained components, they are also made to last. Consistent pellet quality and equipment longevity are guaranteed by routine maintenance.

4. Advantages for the Environment

Farmers can lessen their carbon footprint by using a livestock feed pellet mill to produce feed pellets on-site. Frequent transportation of completed feed or raw materials is reduced by the process, and energy is conserved through resource efficiency. Furthermore, sustainable farming methods are encouraged by the capacity to convert agricultural waste into feed pellets.

Considerations for Purchasing an Electric Feed Pelletizer

To make sure you get the best equipment for your needs, there are a few things to consider if you’re looking to buy a feed pellet-making machine:

Ability: Calculate how much feed you must produce each day or each week. From industrial models for big farms to small-scale devices for domestic usage, machines come in a variety of capacities.

Power Source: Although the focus of this essay is electric machinery, make sure the voltage and power needs are appropriate for your area.

Pellet Size and Die Options: To create pellets of varying sizes for different animals, look for a machine that has interchangeable dies.

Durability and Brand Reputation: To guarantee quality and post-purchase assistance, choose a machine from a reliable manufacturer.

Cost: Examine pellet machine prices from several vendors to identify a model that meets your needs without sacrificing quality.

Location: You may save money on shipping and make maintenance services more accessible by looking for a feed pellet machine for sale nearby.